General

| Engine Configuration | In-Line 6, 4-Stroke-Cycle Diesel |

| Cooling System Capacity | 15.2 L (16 qt) |

| Lube System (refill) | 13-16 L (13.7-16.9 U.S. qts) |

| Bore | 4 in |

| Stroke | 5 in |

| Displacement | 428 in³ |

| Aspiration | Turbocharged-Aftercooled (TA) or Series Turbocharged Aftercooled (TTA) |

| Compression Ratio | 16.5:1 |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Engine Configuration | In-Line 6 |

| Bore | 105 mm (4.1 in) |

| Stroke | 135 mm (5.3 in) |

| Displacement | 7 L (427.7 in³) |

| Cooling System - Capacity | 15.2 L (16 qt) |

| Lube System - Refill | 13-16 L (13.7-16.9 U.S. qts) |

| Aftertreatment | DOC+DPF+SCR |

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

| Length | 1063.7 mm (41.9 in) |

| Width | 753-820.2 mm (29.6-32.3 in) |

| Height | 907 mm (35.7 in) |

| Weight - Net Dry (Basic Operating Engine Without Optional Attachments) | 715 kg (1576 lb) |

Aftertreatment Dimensions (Approximate. Final dimensions dependent on selected options)

| Length | 771-918.7 mm (30.4-36.2 in) |

| Width | 714.4-793 mm (28.1-31.2 in) |

| Height | 468-643.9 mm (18.4-25.3 in) |

| Weight | 90-134 kg (198-295.4 lb) |

| Diameter | 287-337.8 mm (11.3-13.3 in) |

Power Rating

| Minimum Power | 172 HP |

| Maximum Power | 320 HP |

| Rated Speed | 2200 rpm |

| Maximum Torque | 935 lb-ft @ 1400 rpm |

Emission Standards

| Emissions | U.S. EPA & CARB Tier 4 Final, EU Stage V |

Engine Dimensions - Approximate

| Height | 907 mm (35.7 in) |

| Length | 1063.7 mm (41.9 in) |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 715 kg (1576 lb) |

| Width | 753-820.2 mm (29.6-32.3 in) |

| Length | 42 in |

| Weight - Net Dry - Basic Operating Engine Without Optional Attachments | 1,658 lb |

| Width | 31 in |

| Height | 36 in |

Aftertreatment Dimensions - Approximate

| Diameter | 287-337.8 mm (11.3-13.3 in) |

| Height | 453-455 mm (17.8-18.1 in) |

| Length | 610-733 mm (24-28.9 in) |

| Weight | 65-107 kg (143.3-235.9 lb) |

| Width | 623-769 mm (24.5-30.3 in) |

Aftertreatment Dimensions

| Height | 18 in |

| Weight | 236 lb |

| Length | 29 in |

| Width | 30 in |

Aftertreatment Dimensions*

| Diameter | 13 in |

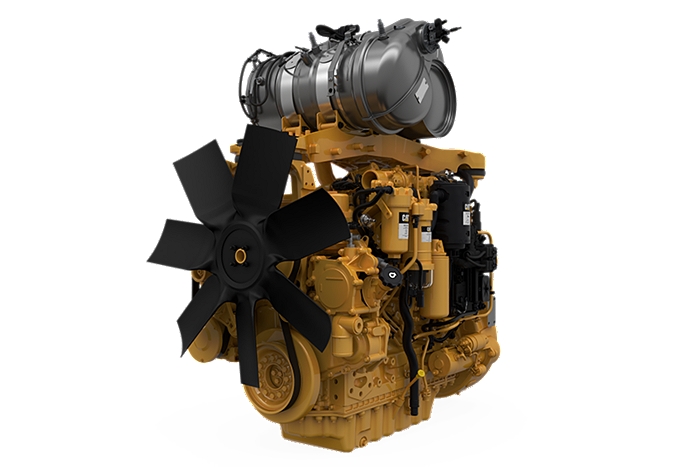

Exterior View

Exterior View