Power Rating

| Minimum Rating | 156 bhp |

| Maximum Rating | 275 bhp |

| Rated Speed | 116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm |

| Minimum Rating | 156 BHP |

| Maximum Rating | 275 BHP |

| Rated Speed | 116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm |

| Maximum Power | 275 HP |

| Maximum Torque | 774 lb-ft @ 1400 rpm |

| Minimum Power | 156 HP |

| Maximum Power | 275 HP |

| Maximum Torque | 774 lb-ft @ 1400 rpm |

| Rated Speed | 116-205 bkW/156-275 bhp @ 2200 rpm, 129 bkW/173 bhp @ 2500 rpm |

| Minimum Power | 156 HP |

Emission Standards

| Emissions | China Stage II, U.S. EPA Tier 3 Equivalent, EU Stage IIIA Equivalent. Designed to meet China Stage III emission standards. |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

| Emissions | China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA |

General

| Engine Configuration | Inline 6, 4-Stroke-Cycle Diesel |

| Bore | 105 mm (4.1 in) |

| Stroke | 135 mm (5.3 in) |

| Displacement | 7.01 L (427.7 in³) |

| Aspiration | Turbocharged Aftercooled (TA) |

| Compression Ratio | 16.8:1 |

| Combustion System | Direct Injection |

| Rotation (from flywheel end) | Counterclockwise |

| Engine Configuration | Inline 6, 4-Stroke-Cycle Diesel |

| Bore | 105 mm (4.1 in) |

| Stroke | 135 mm (5.3 in) |

| Displacement | 7.01 L (427.7 in³) |

| Aspiration | Turbocharged Aftercooled (TA) |

| Compression Ratio | 16.8:1 |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Bore | 4 in |

| Stroke | 5 in |

| Displacement | 428 in³ |

| Aftertreatment | - |

| Engine Configuration | Inline 6, 4-Stroke-Cycle Diesel |

| Bore | 4 in |

| Stroke | 5 in |

| Displacement | 428 in³ |

| Compression Ratio | 16.8:1 |

| Aspiration | Turbocharged Aftercooled (TA) |

| Combustion System | Direct Injection |

| Rotation from Flywheel End | Counterclockwise |

| Aftertreatment | - |

Power Unit Dimensions (Approximate. Final dimensions dependent on selected options)

| Length | 1728 mm (68 in) |

| Width | 788 mm (31 in) |

| Height | 1140 mm (44.8) |

Power Unit Dimensions - Approximate

| Weight - Net Dry - Standard Configuration Without Oil, Cooling, Clutch, Compressor, A/C | 788 kg (1737 lbs) |

| Width | 788 mm (31 in) |

| Height | 1140 mm (44.8) |

| Length | 1728 mm (68 in) |

Power Unit Dimensions

| Weight | 1,737 lb |

| Width | 31 in |

| Length | 68 in |

| Height | 45 in |

| Length | 68 in |

| Width | 31 in |

| Height | 45 in |

| Weight | 1,737 lb |

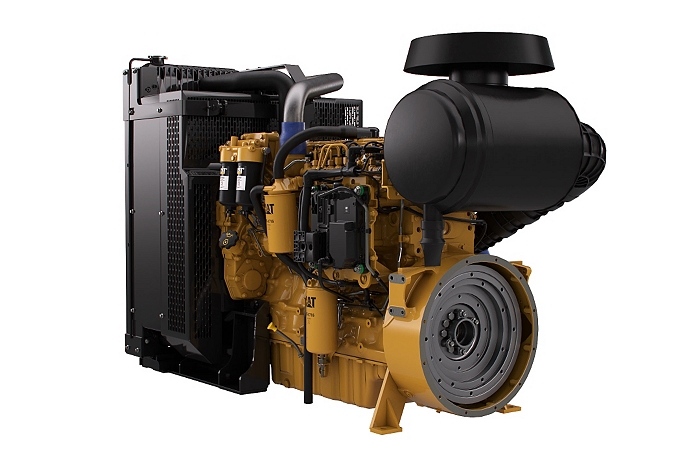

Exterior View

Exterior View