Engine Specifications

| Aspiration | Turbocharged-Aftercooled |

| Fuel System | EUI |

| Oil Change Interval | 1,000 hr |

| Stroke | 12 in |

| Bore | 11 in |

| Displacement | 18,062 in3 |

| Minimum Rating | 7,510 kV·A |

| Maximum Rating | 7,684 kV·A |

| Emissions | IMO Tier 2 / EPA Marine Tier 2 |

| Engine Control | Dual ADEM™ A4 |

| Generator Set Control | Cat® Alarm and Protection System |

| Weight | 145,505 lb |

| Aspiration | Turbocharged-Aftercooled |

| Bore | 11 in |

| Displacement | 18,062 in³ |

| Fuel System | EUI |

| Oil Change Interval | 1,000 h |

| Stroke | 12 in |

Dimensions

| Length | 405 in |

| Height | 161 in |

| Width | 110 in |

| Height | 161 in |

| Length | 405 in |

| Width | 110 in |

Capacity for Liquids

| Cooling System (Engine) | 329 gal |

| Lube Oil System (Refill) | 443 gal |

| Cooling System - Engine | 329 gal (US) |

| Lube Oil System - Refill | 443 gal (US) |

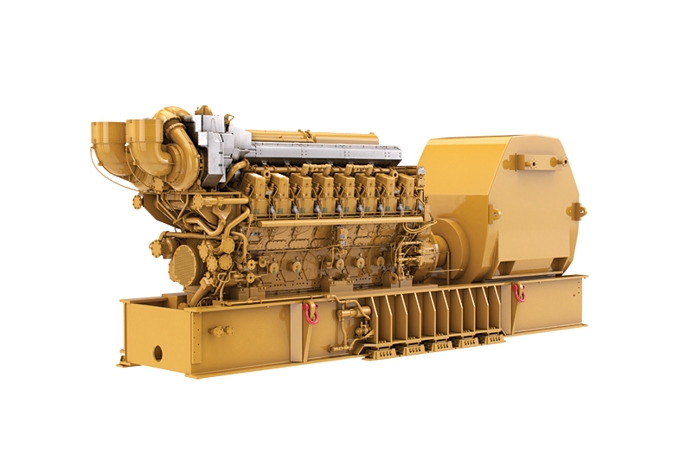

Exterior View

Exterior View