If you haven’t purchased used equipment before, you likely have some questions about the process. While used machinery is often more affordable than new equipment, it may have damaged or worn parts from previous use. Thankfully, many dealers rigorously inspect pre-owned equipment before selling it.

For your peace of mind and to verify the equipment is in good shape, you should ask plenty of questions and carefully assess the used machinery before buying it. Use this guide to cover your bases and ensure you’re comfortable before buying pre-owned equipment. Here’s what to ask when purchasing used equipment.

Important Questions for Buying Used Heavy Machinery

As soon as equipment is purchased and leaves the warehouse, it’s considered used. While some used equipment is in almost new condition, other used machinery may need serious repairs. Before you purchase used heavy equipment, you must evaluate its condition to determine its value.

Use this checklist for buying used heavy equipment to guide your search. Although purchasing used equipment takes research and patience, it can help you save significantly on equipment costs. Because it’s more affordable, buying used can help you access the equipment you need to increase productivity on the jobsite.

How Much Has the Equipment Been Used?

Dealers should have a record of a machine’s hours of use. Equipment can only be expected to run well for so long without needing part replacements and maintenance. If equipment has already been used for many hours, it will likely require more repairs over the rest of its useful lifetime. Purchasing equipment with high hours of use isn’t necessarily a bad decision, but you should be aware that it may be costly to maintain.

Has It Been Regularly Maintained?

Maintenance records can give you a glimpse of a machine’s health and how soon it may need work. Regular maintenance and care will keep parts running properly for much longer. Equipment that hasn’t been regularly maintained may need more work and part replacements in the near future. If there is no maintenance record, consider it a red flag.

Does It Have Full Documentation?

In addition to records for hours of use and maintenance history, heavy equipment has other essential documentation. These records give you a full picture of equipment condition and can increase your confidence in purchasing used machinery. Here’s a list of documents you need to have in your possession before buying used heavy equipment:

- Product identification number (PIN) and serial number

- Uniform Commercial Code (UCC) filings search for liens

- Ownership history and records of ownership changes

- Documentation on whether the equipment was ever seized, stolen or repossessed

- Maintenance and service records

After you purchase equipment, you should receive a proof of purchase and payment receipt. You should also be given the title once the equipment is completely paid for. If this documentation is unavailable for used equipment, think twice about purchasing it. These documents protect you and ensure pre-owned equipment is in good condition, so you won’t have any surprises later.

Are Parts and Services Available?

Used equipment may need more maintenance than new machinery, so it’s important that you can easily access replacement parts and services. It’s better to work with a local dealer if you can, since they often provide parts and maintenance service for the equipment they sell. Even if used equipment is in excellent condition, it will need preventive maintenance and replacement parts eventually.

What Tends to Break for This Equipment?

Every type of equipment has certain parts and systems that tend to break down first. Just because a part tends to break doesn’t mean it will, but it’s good to be aware of what could go wrong. If you research the specific equipment you need, you can check it for the weaknesses common to that type of equipment. You can also assess whether certain replacement parts fit into your budget.

Is the Dealer Trustworthy?

You should only purchase used equipment from a reliable dealer with a good track record. Check for local dealers who’ve worked with other businesses in your community. You can determine their reliability by reading reviews and talking to past customers. The longer they’ve been in business, the more information you have to work with to decide if they’re a good partner for you.

Can You Resell the Equipment?

Before purchasing used equipment, research whether it’s possible to resell it. You may only need pre-owned equipment for a specific project and not want to make a long-term investment in it. If that’s the case, you shouldn’t purchase machinery that will depreciate quickly. Understanding the machine’s resale value can help you price how much it’s worth for your business.

How to Evaluate Used Heavy Equipment

After you find used equipment you’re interested in, you should personally assess it before making the final purchase. Follow these three steps so you can buy used equipment with confidence.

1. Complete a Visual Examination

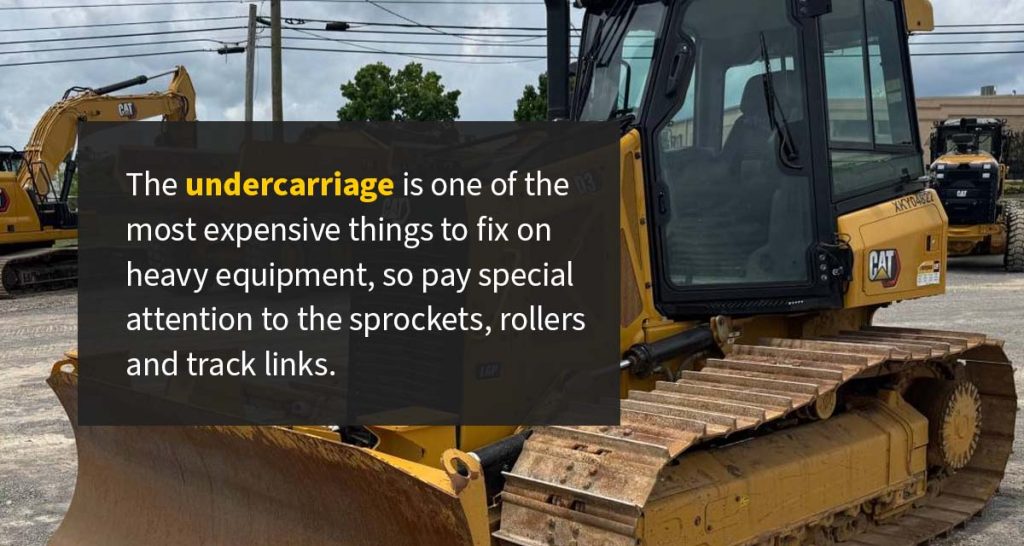

Go look at heavy equipment in person. Walk around it and examine the exterior for cracks, rust and other types of damage. You should check structural components like the frame, boom and stick for damage. Visually examine the tires and tracks to see how deep their treads are.

The undercarriage is one of the most expensive things to fix on heavy equipment, so pay special attention to the sprockets, rollers and track links. Look carefully for rust or missing parts. While it can’t answer all your questions, a careful visual inspection can give you an accurate overview of a used machine’s condition.

2. Dig Deeper Into Components

You should also look over specific components like the engine, hydraulic system, electrical system, cab and controls. These systems are critical to a machine’s working capacity. The best way to test each system is to turn the machine on. Operate the hydraulic system, listen to the engine and test the lights and gauges. Look at the battery and electrical wiring and check hydraulic hoses for leaks.

Look for starting fluid in the toolbox or under the operator seat. If heavy equipment needs starting fluid to start when it’s cold outside, there’s something wrong with the machine. Equipment that’s in top condition shouldn’t require starting fluid, even when the temperatures drop.

3. Run the Equipment

After you’ve looked at specific components, sit in the cab and try moving the equipment like you would at a jobsite. Pay attention to how it feels as you move it around. Are there any strange noises or vibrations? Used equipment will tell you if something is wrong — you just need to listen. If a dealer won’t allow you to personally test equipment, that’s not a good sign.

Find Used Heavy Equipment From Thompson Machinery

Thompson Machinery is the exclusive Cat® dealer for Middle Tennessee, West Tennessee and North Mississippi. Since 1944, we’ve been serving industries like mining, construction, forestry and agriculture with the best in heavy equipment. We can match you with the perfect option to meet your needs, whether you’re looking for new or used heavy equipment.

Our certified used equipment is carefully inspected and qualified before we offer it for sale. We’re confident in each machine’s reliability and offer a one-year or 1,000-hour powertrain warranty for pre-owned equipment so you can have additional peace of mind. In addition to high-quality used equipment, we also offer 24/7 parts and service support.

Choose Thompson Machinery as your total equipment solutions provider. Contact us today to learn how we can support you with used Cat and Allied equipment!