Heavy equipment wears down over time. When that happens, you may decide to rebuild your existing unit or invest in a new or used machine. The right choice depends on the equipment’s reliability, maintenance records and hours.

Explore when you should replace or rebuild heavy equipment and the pros and cons of each option below.

Evaluating the Condition of Your Equipment

Before rebuilding or replacing your machine, assess its value and how it impacts operations. Here’s what to evaluate.

Performance

How the equipment functions gives you a sense of its condition and value. Start with the following indicators:

- Operational reliability: Machines that require frequent adjustments or operate below original specs might indicate mechanical faults. Hydraulic leaks, overheating or reduced engine power can affect jobsite productivity and efficiency.

- Maintenance records: If you’ve had to replace components frequently or upkeep costs keep rising, you may experience diminishing returns. Frequent repairs may indicate a shorter remaining lifespan, which warrants replacing or rebuilding your machine.

- Safety: Older machines often lack modern safety features, and significant wear can compromise structural or component integrity. Check for recurring safety alerts tied to the unit. If operators have reported unusual vibrations, fluid leaks or inconsistent behavior that persists after repairs, it may be time for a rebuild or replacement.

Age and Usage

Heavy equipment’s life expectancy is measured in hours. For example, depending on the model, operating conditions, and upkeep practices, loaders, dozers or excavators can operate for 7,000 to 15,000 hours before requiring an overhaul.

How the equipment was used also matters. Machines operating in harsh environments or on demanding jobsites may wear faster than those used in controlled settings. Additionally, older equipment may lack compatibility with newer attachments or technology, limiting how efficiently it can perform in a modern fleet.

If your equipment has exceeded its typical service life or is approaching the end of its expected hours, consider rebuilding it to extend its value or replacing it with models that have the modern features to streamline operations.

Environmental Impact

Older machines tend to have higher emissions and lower fuel efficiency, and they may not meet current environmental standards. These factors can affect your eligibility for jobs with strict compliance requirements or green certifications.

Rebuilding can reduce waste and extend the use of existing materials. Refurbishment also allows you to integrate more recent components that improve fuel economy or reduce emissions.

Replacing equipment with models designed for higher efficiency and lower emissions can help your business align with environmental goals and industry expectations. If sustainability is part of your value proposition, it may contribute to a stronger brand reputation.

When to Rebuild Equipment

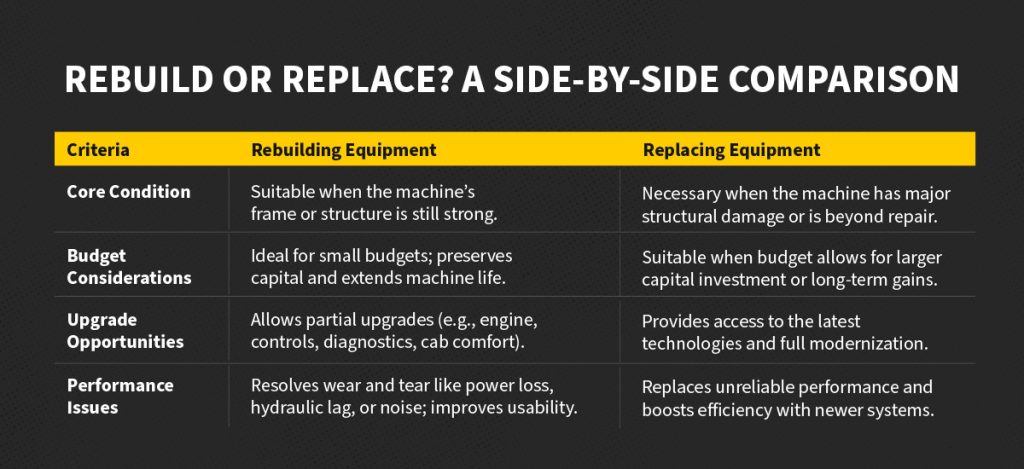

Rebuilding makes sense when the machine’s core is still strong, but major systems need attention to restore full performance. Below are signs you should rebuild your machinery:

- High repair costs: If your equipment needs repairs that exceed minor fixes, consider long-term value. Instead of spending money patching problems as they appear, a rebuild allows you to restore vital systems in a single, planned downtime window. This prevents constant breakdowns and repeated service calls. A rebuild is worthwhile for engine overhauls or hydraulic system replacements. The process restores components that support performance, reliability and safety.

- Significant wear and tear: If your equipment is losing power or operating inefficiently, a rebuild can give it a second wind. Operators may report slow response times, excessive noise or hydraulic lag. A rebuild addresses these issues, restoring smooth operation and improving usability.

- Upgrade opportunities: A rebuild gives you the flexibility to integrate newer components. Upgrades include an efficient engine, digital control panels and modern diagnostics features. You can also enhance operator comfort to reduce fatigue. These advancements maximize the machine’s fit within your current fleet and can extend its life for a few more years.

- Small budget: Rebuilding helps preserve cash flow and capital while getting your machine back into the field. In situations where equipment failure stalls operations but buying new would stretch your budget, a rebuild can help. It enables you to stagger major purchases, reduce downtime and keep projects on track. Suppliers make the most out of available resources to save you money.

Pros and Cons of Rebuilding Heavy Machinery

Rebuilding can be a smart move, but it’s not the right fit for every situation. Here are some advantages and considerations to make an informed decision.

Pros of Rebuilding Heavy Machinery

Refurbishing allows you to tailor equipment to suit your operations, which can boost productivity. Here’s why it’s worth the investment:

- Improves performance: A rebuild restores engines, transmissions, hydraulics and electronics, helping bring performance closer to factory standards. You may experience fewer breakdowns, improved fuel efficiency and more responsive system controls. Rebuilt equipment often delivers like-new functionality at a fraction of the cost of a new machine.

- Extends equipment life: A comprehensive rebuild extends the usable life of your machine. This extension allows you to reap more value from your original investment. It also delays the need for frequent repairs and major replacements, giving you more stability across your fleet planning.

- Warranties and support: Rebuild programs come with extended warranties and new coverage on all the parts replaced during the rebuild process. Service support is also available after the rebuild, giving owners added peace of mind.

- Customization: Rebuilding lets you attune the machine to current job needs through upgraded attachments, modernized controls or compliance-focused retrofits. This flexibility is valuable when working in specialized applications or regulated environments.

Considerations of Rebuilding Heavy Machinery

Despite the advantages of rebuilding heavy equipment, there are aspects to consider. These factors include:

- Costs: Although more cost-effective than buying new, a full rebuild can cost approximately 60% of a replacement. Labor is often extensive because machines must be dismantled, inspected and reassembled. You’ll also need to factor in equipment downtime during the rebuild, which can temporarily impact job schedules.

- Limited parts: For older models, original equipment manufacturer (OEM) parts may be obsolete or available only through limited channels. Substitute parts are sometimes viable, but they may not meet original performance standards. Delays in sourcing rare components can lead to extended rebuild timelines and reduced operational readiness.

When to Replace Equipment

Whether you opt for a new or preowned model, a replacement is a good option when safety, efficiency or compliance are concerns. Here’s when to replace heavy equipment:

- Beyond repair: If a machine has major structural damage, experiences repeated failures or safety issues, replacement is a responsible choice. Operating compromised machinery puts workers at risk and exposes your business to liability and unplanned downtime.

- Time constraints: If equipment is crucial to your workflow and a rebuild would take long, replacing the machine allows you to maximize uptime. New or preowned equipment availability with dealer support can make this transition smoother and faster.

- Limited parts or outdated technology: As machines age or become discontinued, replacement parts can become harder to source or more expensive to procure. Older machines may lack compatibility with modern technologies, which limits integration with your current fleet of workflows. Replacing outdated units gives you access to the latest technology to improve productivity and safety.

- Reduced efficiency: If your current units drain resources because of frequent repairs or poor fuel economy, a replacement may pay off. New machines offer better fuel efficiency, lower maintenance needs and fewer unplanned breakdowns. Up-to-date engines and systems run cleaner and more efficiently, cutting emissions and fuel costs.

- Decreased productivity: Sluggish hydraulics, unreliable controls and outdated cab features can frustrate operators and slow down work. When your team spends more time compensating for inefficiencies than getting the job done, consider a replacement. Upgrading units improves responsiveness, comfort and output.

Pros and Cons of Replacing Heavy Machinery

Investing in new or used machinery can boost productivity and keep projects on track, but this option has some drawbacks. Explore the perks and limitations of replacing your machine.

Pros of Replacing Heavy Machinery

Replacing your equipment allows you to purchase a model tailored to your needs. The benefits of replacing your machine include:

- Longer life expectancy: New equipment gives you a fresh life cycle with zero operational hours and minimal wear, which means fewer repairs and more predictable performance. With proper maintenance, you can expect years of reliable use.

- Improved performance: The latest machines have faster cycle times, better hydraulic response and intuitive controls, which improve jobsite productivity. Operators may experience smooth handling and greater comfort, which reduces fatigue and increases efficiency.

- Lower operating costs: Modern equipment is fuel-efficient, reduces emissions and has extended service intervals. Updated systems and diagnostics make monitoring usage easier and scheduling preventive maintenance easier. These operational savings may offset the initial purchase cost.

- Improved safety features: New models have improved safety systems such as rollover protection structures and auto shutoffs. Some are built to meet evolving regulatory and industry standards, helping your business stay compliant and avoid violations.

- Warranty and dealer support: New equipment purchases come with a warranty covering parts and labor. For peace of mind, you can also pair this with operator training, service contracts and advanced diagnostics.

Considerations When Replacing Heavy Machinery

While there are various advantages of investing in the latest equipment, fleet owners and managers should consider the following:

- High initial investment: Purchasing new equipment typically requires a substantial upfront cost, which may strain budgets if not planned for or financed properly. Even with financing, factor in down payments and interest, especially when replacing multiple machines across a fleet.

- Learning curve: New machines often come with the latest technology and features that may require additional training for your team. This learning curve can lead to temporary slowdowns, operator errors or underutilized features. Investing in operator training can ease the transition.

- Lead times: Waiting for a new model to arrive might rival or exceed the downtime of a rebuild, unless you opt for in-stock used units or work with a dealer who offers interim rental solutions.

Cost Impact of Rebuilding or Replacing Heavy Equipment

Expenses associated with rebuilding or replacing heavy equipment depend on your budget, maintenance needs and operations. Here’s how each option impacts costs.

Cost Considerations When Rebuilding

Rebuilding is an appealing and cost-effective option because of the tailored support and various upgrade options. However, owners and managers should factor in the following:

- 50% rule: If the cost to rebuild is less than 50% of the cost of a new machine, it’s typically a financially sound move. However, rebuilding equipment that is essential to daily operations may be worthwhile at approximately 60% if downtime costs are high and replacements aren’t readily available.

- Extent of damage: Minor overhauls can be affordable and efficient. However, if the damage is structural or affects multiple systems, rebuilds can become complex and quickly approach new equipment pricing. You also need to factor in inspection costs and tear-down assessments to determine the extent of repairs.

- Labor and parts: Labor costs vary depending on the technician’s expertise and availability. Some rebuilds require specialized skills that may increase shop time and rates. Older models may require hard-to-source parts or remanufactured components, which can introduce cost and lead time variability. Partnering with an equipment solutions provider gives you access to factory-trained technicians and genuine parts, saving you time and money.

Cost Considerations When Replacing

Replacing your machine allows you to upgrade for better performance, efficiency and safety. However, be sure to consider the following:

- Purchase price: A new or used machine is an investment that may reach six figures, depending on the class and configurations. However, dealers offer flexible financing solutions to ease cash flow constraints.

- Resale value: New equipment depreciates steeply within the first 12 months, so factor residual value into your long-term financial planning. Some models and brands may hold their value better because of strong resale demand, low operating hours or dealer-backed maintenance records. If you plan to cycle machines every few years, factor in resale in your total cost equation.

- Operator training: New models may require operator training to maximize their capabilities. While instruction is a short-term cost, undertrained operators can cause inefficiencies or equipment damage. Partner with dealers who offer operator training to support adoption.

- Maintenance costs: While replacement reduces upfront repair costs, new or used machines require care and regular service to maximize lifespan and return on investment.

Rebuild or Replace Your Heavy Equipment With Thompson Machinery

Thompson Machinery is an authorized Cat® dealer for Middle Tennessee, West Tennessee and North Mississippi. Our solutions are backed by over 75 years of experience and factory-trained expertise. We work with fleet owners and managers across various industries and are committed to providing unmatched customer service.

We provide rebuild programs, new and used equipment, and affordable financing options. Our team tailors support to your budget and operations. Contact us today to speak to an expert.